US $33.00 US $31.50 / Pcs

10 Pcs Minimum Order (MOQ)

Category :

LED Lights

14 year

Packaging & Delivery

| Quantity(Piece) | 1 - 100 | >100 |

| Est. Time(days) | 10 | To be negotiated |

Product Description

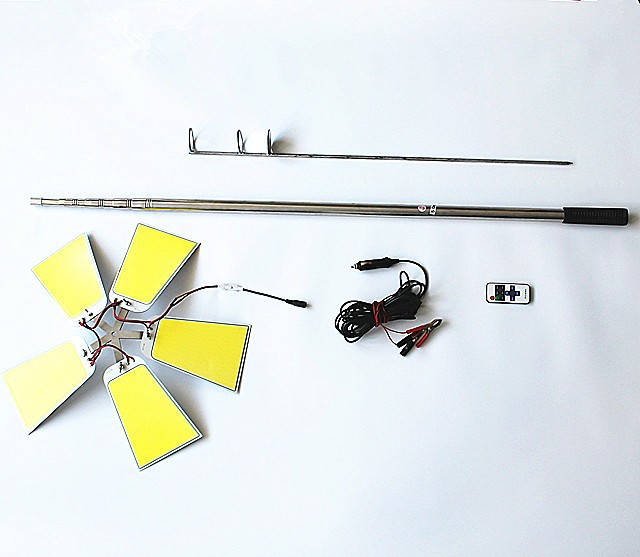

Voltage | 12V | CCT | 8000K |

Material | Aluminum | Application | Out door camp |

Luminous | 100-130LM/W | Warranty | 1 year |

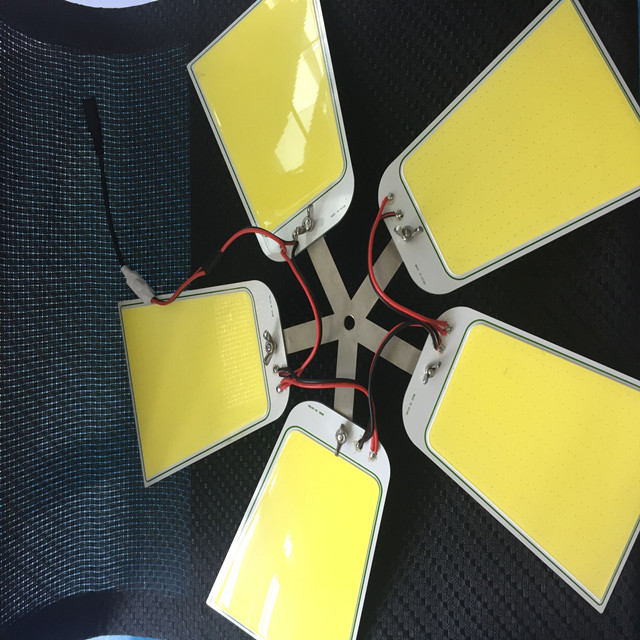

COB Advantage

COB, (Chips on Board) , multi LED chips are packaged together as one lighting module.

Cob LED Light Source is a High efficiency, integrated, surface light source technology that mount the led chip on the high reflective metal substrate.

This technology without the conception of holder, no plating, no Reflow soldering, no patch process, reduce the 30% process, so it also cuts down about 30% cost.

Production Process of COB LED

1.Die Bond

Use the colloid to mount the led chip on the designated area, then makes a conductive passages or heat passages, prepare for wire welding.

2. Wire Welding

Use wire to connect the led chip to PCB circuitry.

3. Glue Dotting

Cover a special glue on the surface of the led chip, this step is to protect the led chip and fixed it.

4. Surround Edge

Use special glue to surround the edge of cob led, this step is determine the lighting area and it is prepared for glue filling.

5. Glue Filling

Fill the glue cover surface of cob led,(the glue on this step will determine the color temperature if the Color is White;

for other color, such yellow, red, green, it plays a protective role and ensure the light evenly).

6. Machine Baking

After the glue filling, we need to bake the cob led, and make sure the glue adhesive on the surface of the PCB board.

7. Testing

After baking, we will pick out the product with bad appearance, then testing for 48 hours to check the quality.

8. Packing

The last step is packing, When the above process all fished, all product will be packed in dust-free workshop with blister package.